HOW DOES TOM’S TUMBLER™ COMPARE TO OTHER TRIMMERS?

Don’t just believe us. Compare our tumbler output and savings to comparable trimmers here.

Whether you wet trim or dry trim, process small volumes or large volumes, Tom's is hands down the best option among the trimmers. Our tumblers are the most gentle, most efficient, and least expensive of any trimmer on the market. They’re easy to use, quiet, and effortless to maintain. You also get the best customer service anywhere. But most importantly, our grower-invented tumble trimmers produce a trimmed flower that doesn't look machine trimmed. What you get is an unmatched hand-trimmed quality every single time. So why would you choose another machine?

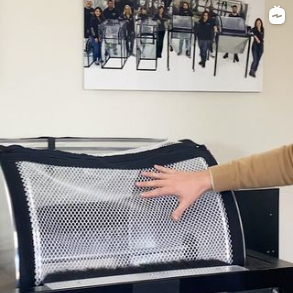

The Tom's Tumbler™ concept is simple. Tumbling dry flower in a nylon mesh net for 3-4 minutes gently knocks the sugar leaves off the flower without impacting the structure. No blades needed. No noisy motor or vacuum. No oils. In a fraction of the time it takes to hand trim, you have hand-trimmed quality flower ready to go to market. But don't take our simple design for granted. It works great because your flowers don't need a lot of metal or processing. They need only gentle tumbling in Tom's custom-barrel, hand-made MeshNets to achieve perfection.

Need more incentive to buy Tom's tumble trimmers? Check out all the reasons below, our comparisons to other trimmers, and then use our calculator to choose the right-sized tumbler for you.

Tom designed his tumblers to work without using metal blades. They rely instead on food-grade nylon nets and kief nets to process your flower. The flowers actually do the trimming as they tumble over each other in the net. In less than 5 minutes, your product is more than 90% trimmed.

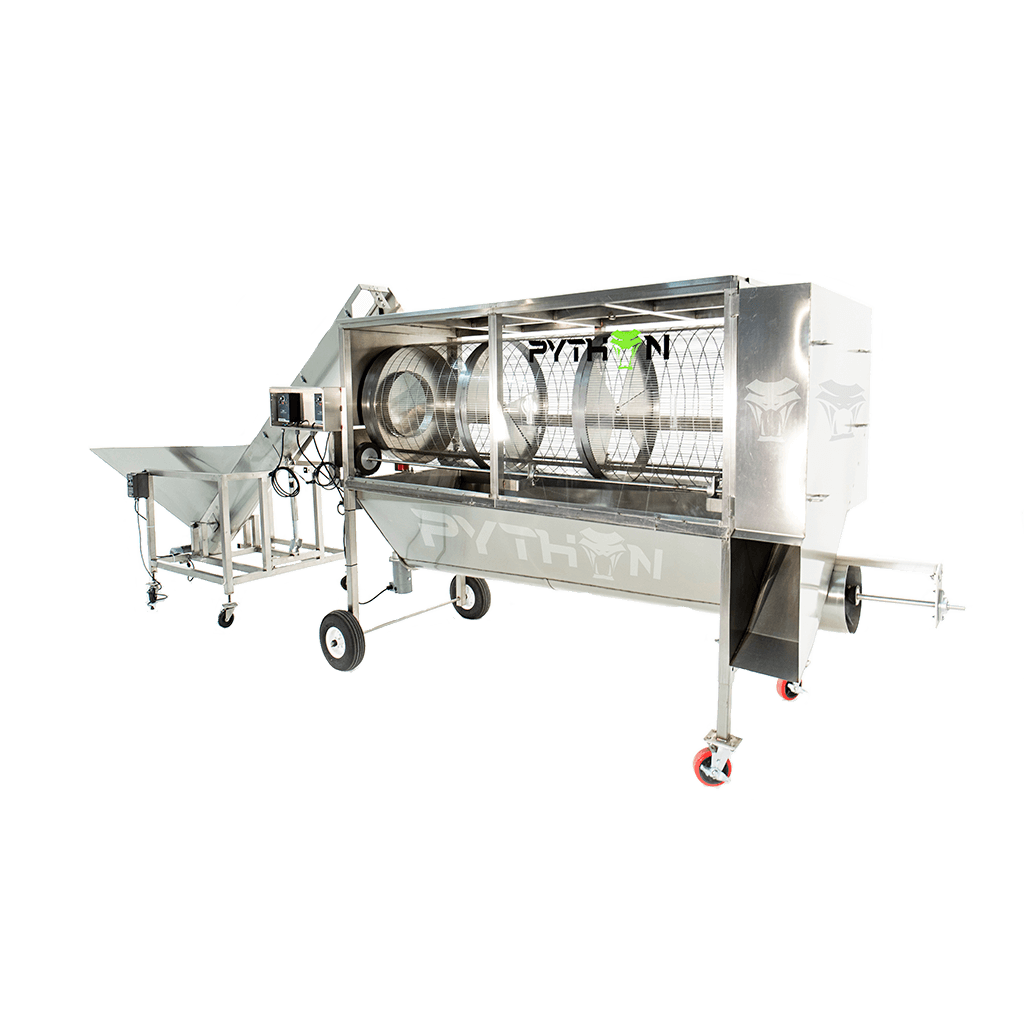

Tom’s tumblers produce the highest output per hour, saving you time and money. Our batch machines trim 6-100 lbs per hour, depending on the model, while industrial-grade Python continuous feed tumblers trim 200-1200 lbs per hour depending on the model.

Tom designed the tumbler because he was tired of hand trimming and didn't like the way other trimmers mangled his flower. One day he put some flower into a fishing net and found that gentle shaking trimmed the flowers. A year of development led to the TTT 1600 Trimmer, which sold quickly. The nylon mesh on the tumbler today mimics the fishing net. Three minutes of tumbling is all that is needed to trim 85% or more of the sugar leaves from your flower without losing its shape or crystals. We called it the Flower-lover.

Because of Tom's commitment to keeping prices low, our trimmers are the most affordable on the market. Our TTT 1600 is less than $500 and trims 6-8 pounds per hour by simply turning the hand crank. It’s easy, fast, and perfect for the small grower. Even our commercial models are thousands below our competitors. Check out our price comparisons at the bottom of the page!

Tom worked hard to design a product that would be easy to assemble, lightweight to ship, but built to last the wear and tear of years of trimming. The recycled, furniture-grade PVC that we sourced for the smaller models is virtually unbreakable and is environmentally friendly. Our batch machines can be assembled in less than 15 minutes and are easy to clean. They can even be disassembled for storage.

Invented by a grower for growers, Tom brings his decades of experience to designing his products and supporting his customers. Every day, Tom talks to growers to learn about their needs and help them find solutions. At Tom’s Tumbler™, our team is dedicated to ensuring our customers have a great experience with his products.

We've sold thousands of trimmers since coming to the market six years ago, and we always hear the same rave reviews from our customers. Growers love the simplicity, speed, and gentle mesh nets of our tumblers. But they also love our customer service and the fact that they can call and talk to Tom himself.

Made in the USA, our tumblers are manufactured from the highest quality materials and built to last. Even our furniture-grade PVC models are virtually unbreakable and are still used regularly by our earliest customers five years later. The Pythons are fully stainless steel with heavy-duty motors. These are built to process hundreds of thousands of pounds per year without any downtime.

Don’t just believe us. Compare our tumbler output and savings to comparable trimmers here.